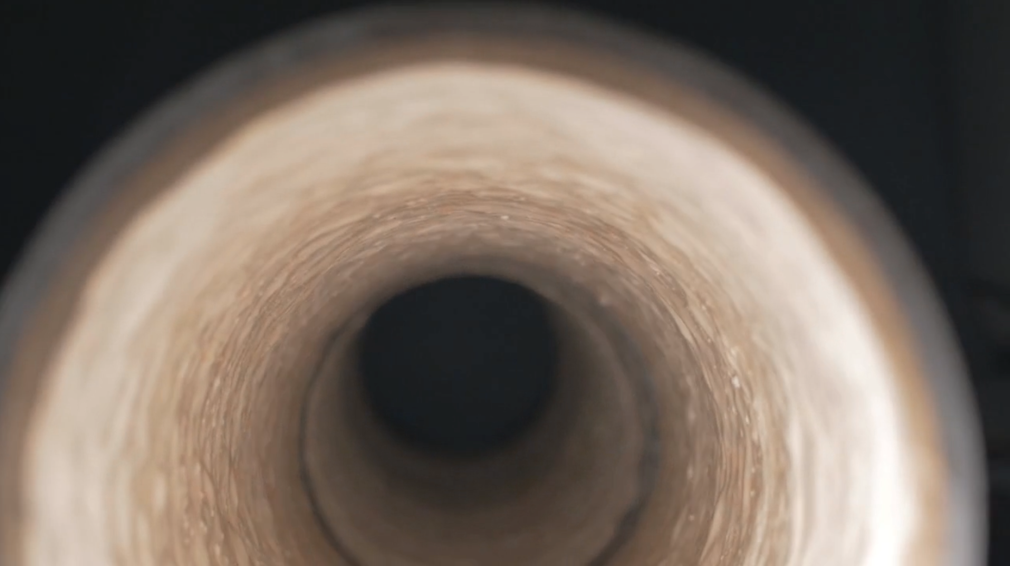

The pipe-in-pipe process before the renovation

A safe, high-quality and environmentally friendly process

Is your sewer pipe, regardless of whether it is plastic, Eternit, cast iron, stainless steel or copper, leaking or showing its age? We can help you with our high-quality, environmentally friendly process.

We have already successfully used the pipe-in-pipe process in over a thousand lines. We use this innovative renovation technique successfully throughout Switzerland every day.

Fixed costs and clear planning principles

The costs of this innovative renovation technique (pipe-in-pipe method) can be calculated very precisely thanks to the empirical values available, as can the duration of the renovation. By means of this technology we can save the customer up to two thirds of the time required compared to replacing the pipelines completely.

The pipe-in-pipe procedure during the renovation

It is possible to selectively repair damage applying the innovative procedure. Using our method, it is not (normally) necessary to open up or expose walls and ceilings as well as completely renew of the lines. The pipe renovation is only carried out in the case of existing renovation objects. This means that there are no further expenses for painters, plasterers or tilers. In addition, thanks to the fast drying time, the renovation work on the pipelines can be carried out in one step and within a day, so the sewage network can be put back into operation after the renovation. In addition, not all water-carrying pipes have to be shut down at the same time, as the procedure is usually carried out in sections.

Environmentally friendly process

The new stand-alone tube does not contain any solvents, styrene or carcinogens and is therefore environmentally and user-friendly.

The pipe-in-pipe procedure during the renovation

It is possible to selectively repair damage applying the innovative procedure. Using our method, it is not (normally) necessary to open up or expose walls and ceilings as well as completely renew of the lines. The pipe renovation is only carried out in the case of existing renovation objects. This means that there are no further expenses for painters, plasterers or tilers. In addition, thanks to the fast drying time, the renovation work on the pipelines can be carried out in one step and within a day, so the sewage network can be put back into operation after the renovation. In addition, not all water-carrying pipes have to be shut down at the same time, as the procedure is usually carried out in sections.

Environmentally friendly process

The new stand-alone tube does not contain any solvents, styrene or carcinogens and is therefore environmentally and user-friendly.

The pipe-in-pipe process after the renovation

After the renovation, the customer has a new plastic pipe.

The new independent tube is very durable and withstands pressure as well as chemical substances and mixtures, such as cleaning agents or hot fat mixtures. In addition, it is extremely resistant to temperature fluctuations and has high impact resistance at low temperatures.

The elasticity prevents new brittleness, cracks and stresses that can occur due to thermal expansion or other mechanical stresses.